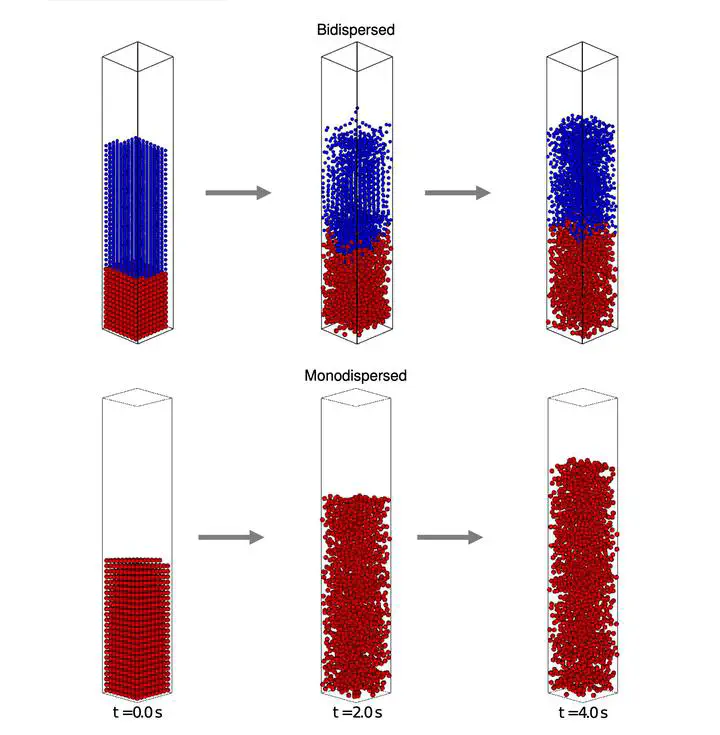

Comparison of the properties of segregated layers in a bidispersed fluidized bed to those of a monodispersed fluidized bed

Abstract

Since industrial fluidized-bed reactors typically operate with polydispersed particles, the ability to approximate such reactors as the superposition of corresponding monodispersed fluidized beds would greatly simplify their design and operation. To evaluate the validity of superposition of monodispersed reactor behavior, we evaluate the effects of bidispersity by comparing three-dimensional liquid-solid monodispersed and segregated bidipsersed fluidized beds. Simulations were conducted using the Immersed Boundary Method (IBM) with direct forcing in a periodic domain and with particle Reynolds numbers of 20-70 based on the largest particle diameter. We show that the volume fraction, kinematic wave speed, particle velocity fluctuations, and collisional and hydrodynamic stresses in the segregated layers of a bidispersed fluidized bed can be well approximated by the corresponding properties of a monodispersed fluidized bed. In the transition region between the layers, only the volume fraction and collision stresses monotonically decrease with height. At low Reynolds numbers, particle velocity fluctuations in the upper layers are the largest. As the particle Reynolds number increases, particle velocity fluctuations in the transition and lower layers become the largest sequentially. At intermediate particle Reynolds numbers, the hydrodynamic stresses in the transition region are greater than those in the upper and lower layers. As the particle Reynolds number increases, the difference between the hydrodynamic stresses in the transition layer and the two layers becomes more significant. This work demonstrates that, despite the clear segregation into layers that behave like monodispersed beds, the transition region is governed by complex bidispersed mechanisms that cannot be explained in terms of the particle behavior in the segregated layers. Overall, particle dynamics of the segregated layers in the bidispersed fluidized bed can be approximated with the corresponding monodispersed layers. The result implies that industrial applications such as wastewater treatment performance in bidispersed or polydispersed fluidized beds can be predicted with results from past numerical or experimental studies of monodispersed fluidized beds.